A common resume challenge faced by a welder fabricator is demonstrating their technical skills and experience in a way that stands out to potential employers. Our guide can assist with this issue by providing industry-specific tips on how to effectively highlight your welding and fabrication competencies, using quantifiable achievements and relevant keywords to catch an employer's attention.

Dive into our welder fabricator resume guide to:

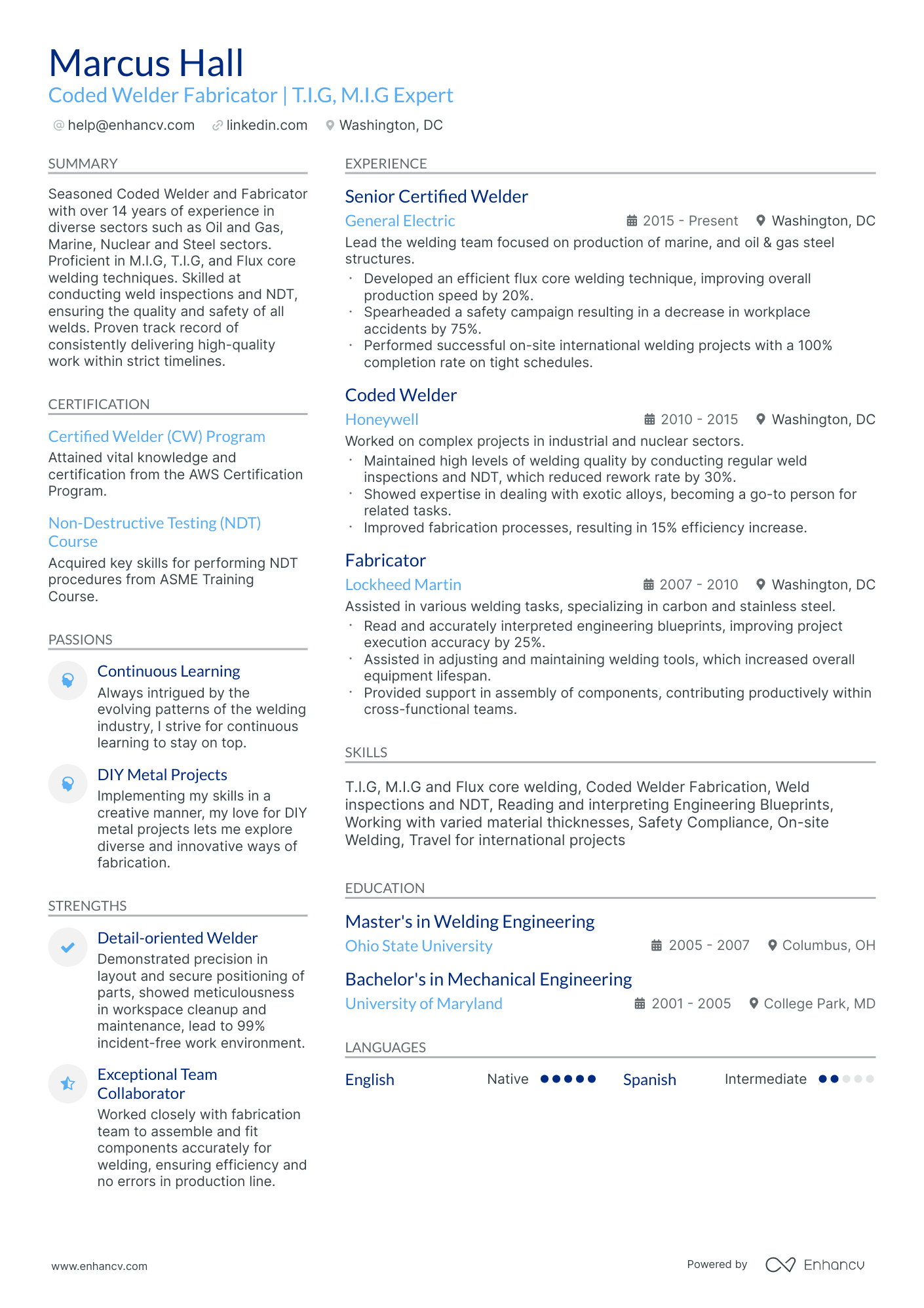

- Explore top-tier resume examples, offering insights into the industry's best practices.

- Enhance sections like experience, education, and achievements with expert advice.

- Articulate your technical prowess and personal attributes, setting you apart from other candidates.

- Sharpen your focus on the distinct skills that make your welder fabricator resume resonate with recruiters.

Recommended reads:

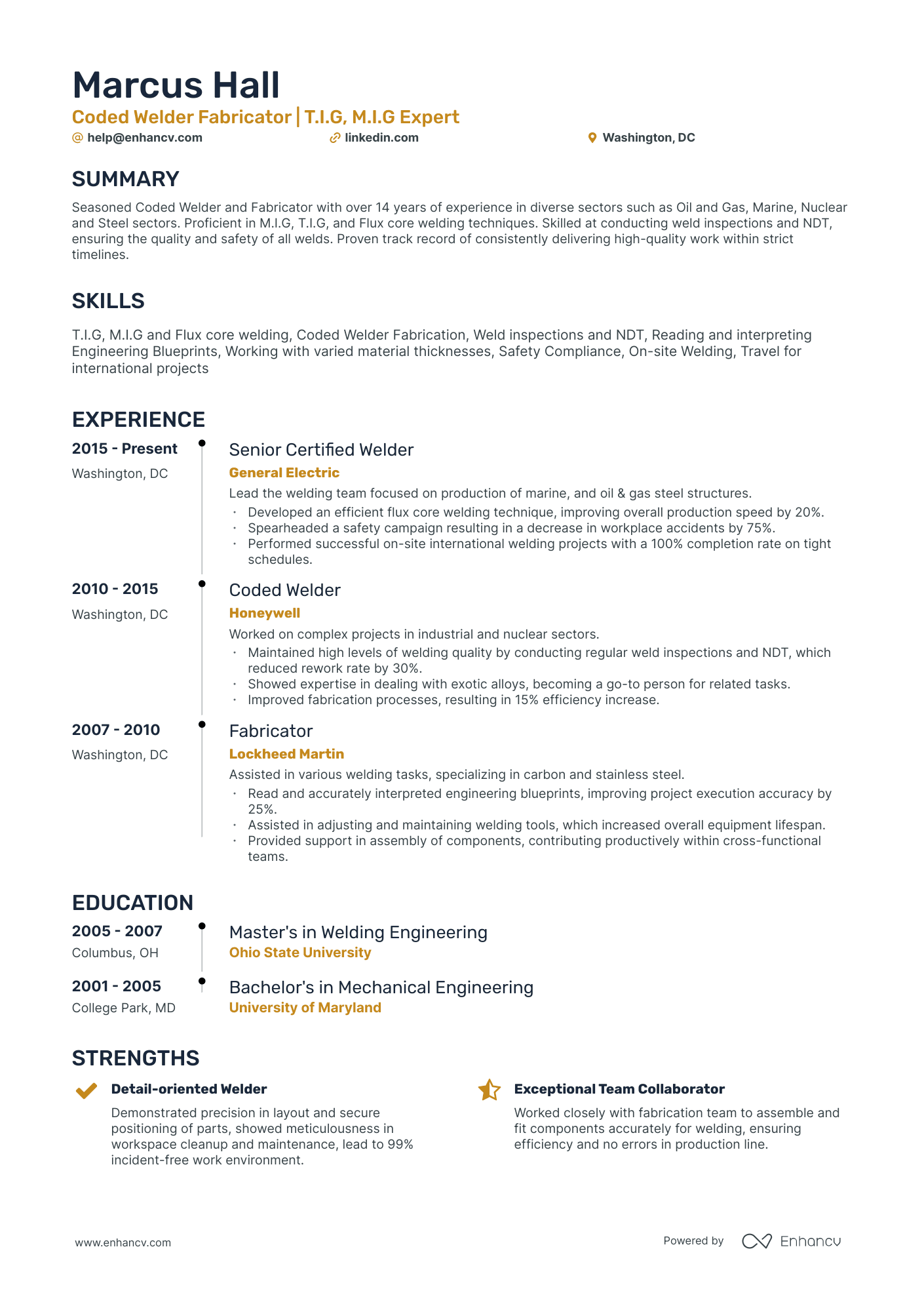

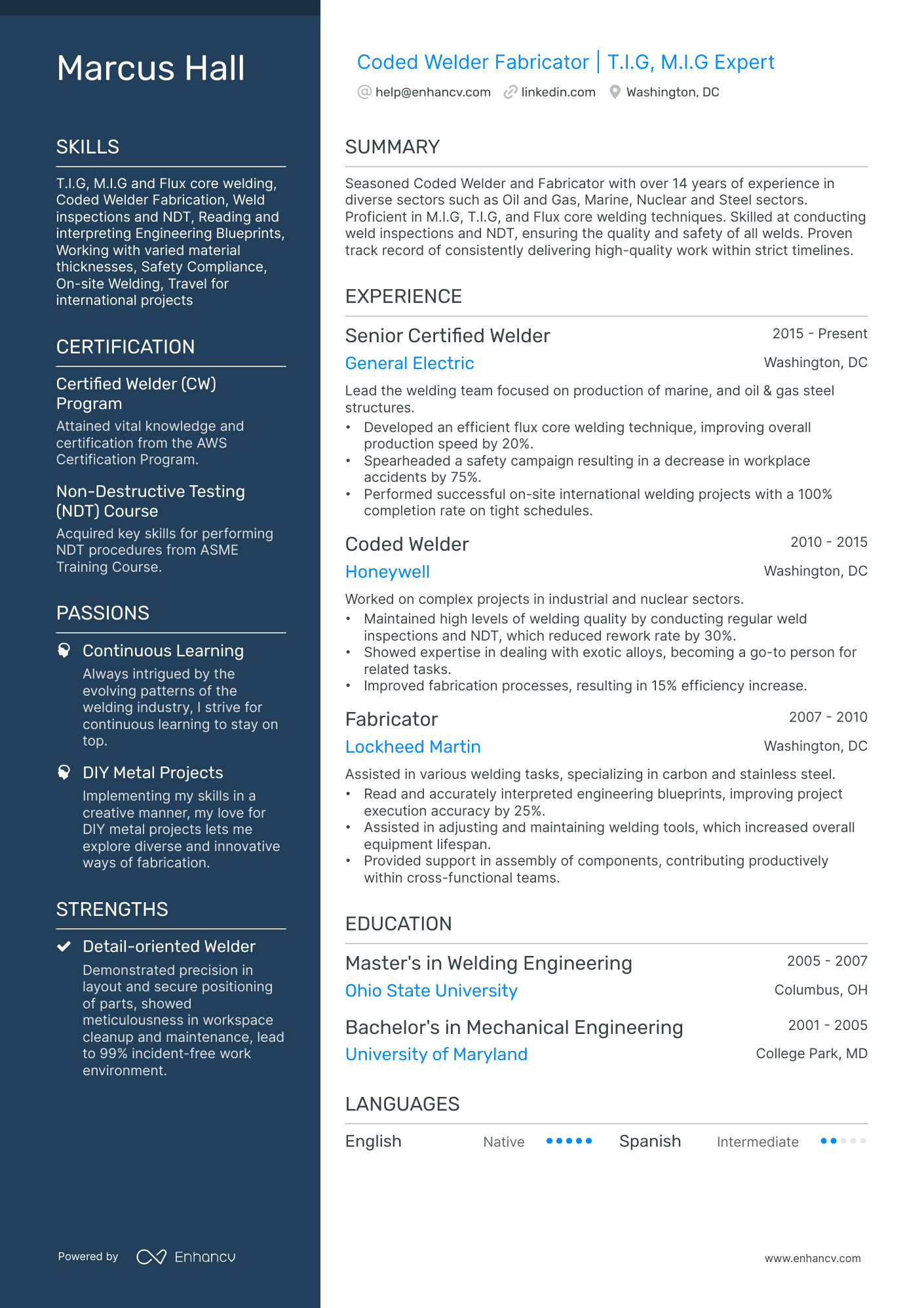

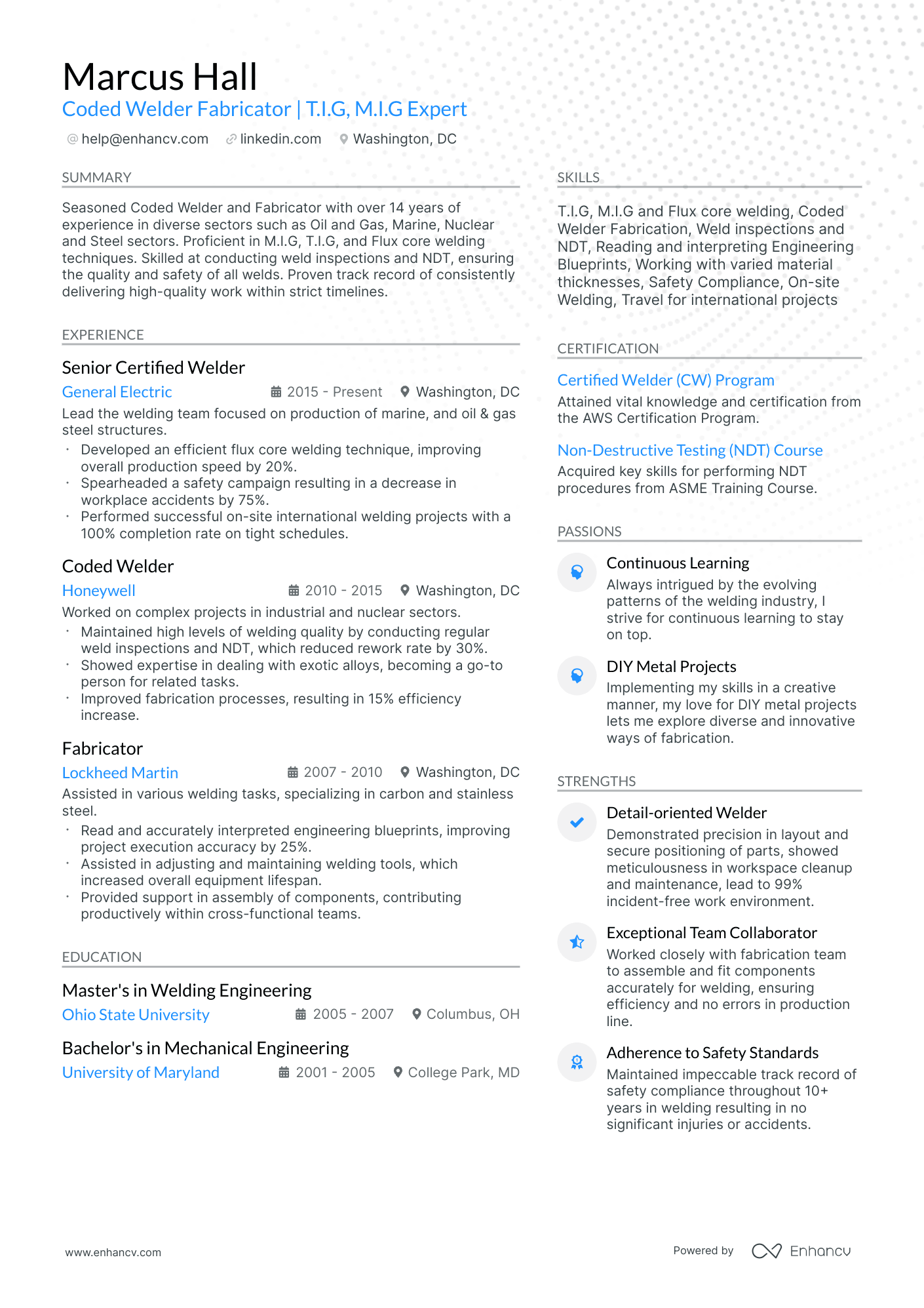

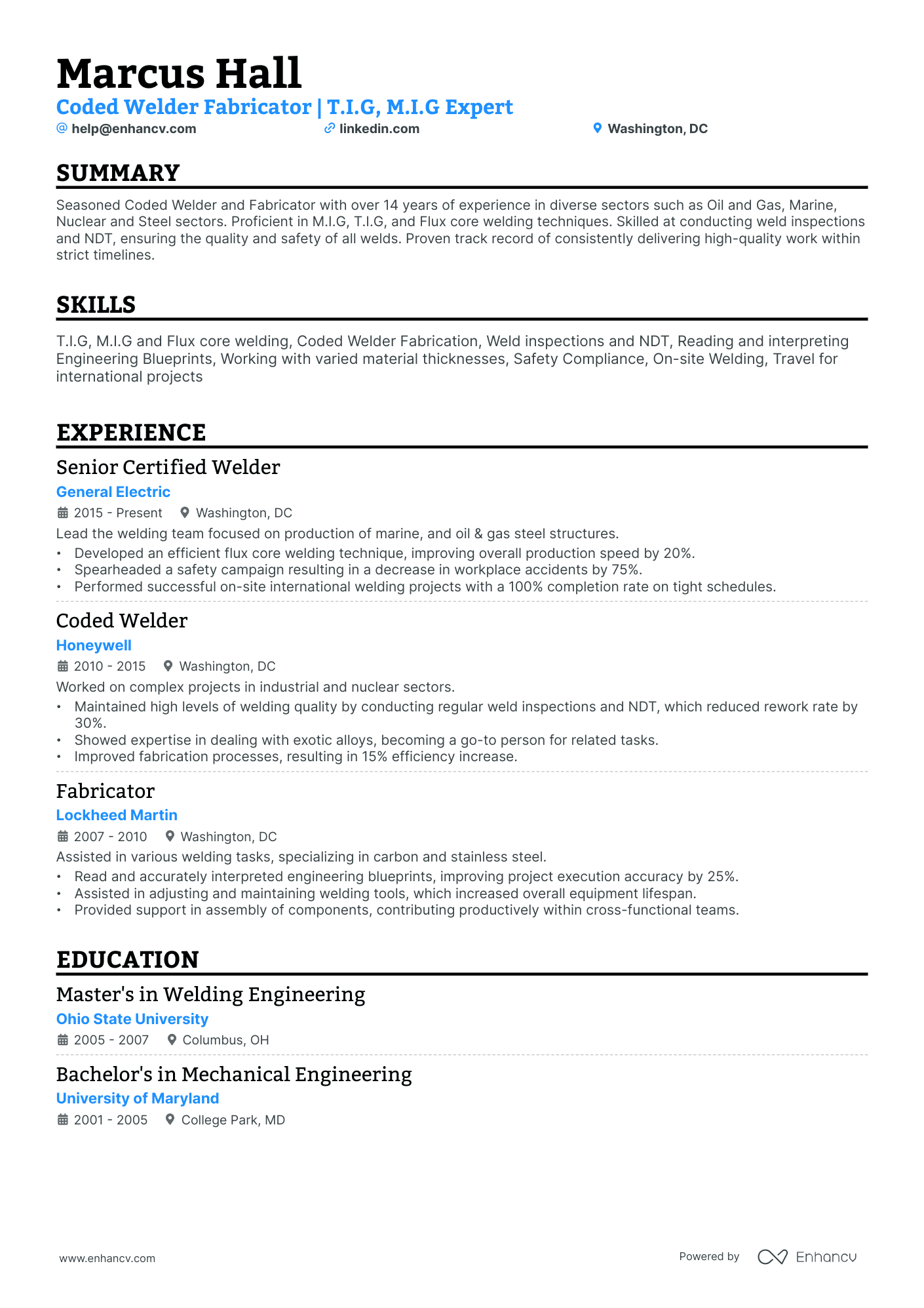

crafting a stellar welder fabricator resume format

Navigating the maze of resume formatting can be challenging. But understanding what recruiters prioritize can make the process smoother.

Wondering about the optimal format, the importance of certain sections, or how to detail your experience? Here's a blueprint for a polished resume:

- Adopt the reverse-chronological resume format. By spotlighting your latest roles upfront, you offer recruiters a snapshot of your career trajectory and recent accomplishments.

- Your header isn't just a formality. Beyond basic contact information, consider adding a link to your portfolio and a headline that encapsulates a significant achievement or your current role.

- Distill your content to the most pertinent details, ideally fitting within a two-page limit. Every line should reinforce your candidacy for the welder fabricator role.

- To preserve your resume's layout across different devices and platforms, save it as a PDF.

The layout of a resume can differ by region – Canadian resumes may use a distinct format.

Upload your resume

Drop your resume here or choose a file. PDF & DOCX only. Max 2MB file size.

Pro tip

Make sure your resume is ATS compliant and catches the recruiters' attention by tailoring your experience to the specific job requirements. Quantify and highlight why you're the best candidate for the role on the first page of your resume.

Essential sections for a standout welder fabricator resume:

- The top section should combine your header—with accurate contact details—and a concise summary or objective that encapsulates your professional achievements.

- An experience section that chronicles your career trajectory and how each role contributed to your professional development.

- Highlight significant achievements that demonstrate the practical application of your skills, leading to tangible results.

- Include industry-recognized certifications to underscore your technical proficiency or interpersonal skills.

- Detail your educational background relevant to the field.

What recruiters want to see on your resume:

- Experience and Skills in Welding: Detailed information about the candidate's experience in different welding techniques such as MIG, TIG, and stick welding. Knowledge of working with a variety of materials such as steel, aluminum, and stainless steel is highly valuable.

- Fabrication Proficiency: Demonstrated ability to read and interpret blueprints and engineering plans. The capacity to fabricate structures or components from raw materials, using appropriate tools and equipment.

- Quality Control: Experience implementing quality control measures to ensure that the final product meets the set specifications and standards. Understanding of relevant testing methods and equipment.

- Safety Compliance: Familiarity with safety regulations and procedures, personal protective equipment (PPE), and safe handling of welding tools and machinery. Certifications or training in workplace safety can be a plus.

- Physical Stamina and Precision: As the job often involves lifting heavy materials and precision work, recruiters would value those who can demonstrate physical stamina and hand-eye coordination. Any tangible proof of these qualities from past experiences would be beneficial.

Recommended reads:

Writing your welder fabricator resume experience

Here are some quick tips on how to curate your welder fabricator professional experience:

- Always ensure that you quantify your achievements by implementing the Situation-Task-Action-Result framework;

- When writing each experience bullet, make sure you're using active voice;

- Stand out by including personal skills you've grown while at the job;

- Be specific about your professional experience - it's not enough to say you have great communication skills, but rather explain what your communication track record led to?

Wondering how other professionals in the industry are presenting their job-winning experience? Check out how these welder fabricator professionals put some of these best practices into action:

- Performed welding and fabrication tasks using MIG and TIG techniques, ensuring high-quality welds and structural integrity.

- Assembled and welded components for industrial machinery, resulting in increased production efficiency by 20%.

- Collaborated with engineering team to develop welding procedures and interpret blueprints for accurate fabrication.

- Operated various power tools and equipment, including plasma cutters, grinders, and drill presses.

- Maintained a safe working environment by adhering to all safety regulations and wearing appropriate protective gear.

- Fabricated metal structures for commercial construction projects, ensuring precise measurements and adherence to architectural specifications.

- Welded stainless steel pipes for food processing equipment, meeting strict sanitary standards and facilitating efficient production processes.

- Utilized CNC machinery to cut and shape metal components, optimizing material usage and reducing waste by 15%.

- Collaborated with project managers to develop detailed work plans and schedules, ensuring timely completion of fabrication projects.

- Conducted quality inspections on finished products, identifying defects and implementing corrective measures.

- Specialized in aluminum welding for aerospace industry, ensuring compliance with stringent quality standards and specifications.

- Fabricated customized metal parts for automotive prototypes, contributing to the development of innovative vehicle designs.

- Operated robotic welding systems to enhance production speed and accuracy, resulting in a 30% reduction in manufacturing time.

- Collaborated with design engineers to optimize welding processes, leading to a 25% increase in structural integrity.

- Trained and mentored junior welders on advanced techniques and safety practices, fostering a skilled and knowledgeable workforce.

- Performed on-site welding repairs for heavy machinery in mining operations, minimizing downtime and maximizing productivity.

- Fabricated and installed ornamental metalwork for high-end architectural projects, meeting intricate design requirements.

- Welded pressure vessels for the oil and gas industry, ensuring compliance with industry regulations and quality standards.

- Collaborated with project managers to estimate material and labor costs, optimizing project budgets and reducing expenses by 10%.

- Implemented preventative maintenance procedures for welding equipment, resulting in a 20% decrease in equipment breakdowns.

- Specialized in underwater welding for offshore oil rigs, executing complex repair tasks at depths of up to 200 feet.

- Welded and fabricated stainless steel tanks for chemical processing plants, ensuring leak-proof and corrosion-resistant structures.

- Operated computer-controlled welding machines for precise and automated fabrication, improving overall production efficiency by 25%.

- Collaborated with engineering teams to develop innovative welding techniques, resulting in cost savings of $50,000 per project.

- Conducted non-destructive testing on welded joints using ultrasonic and X-ray methods, ensuring high-quality weld integrity.

- Fabricated and installed structural steel components for large-scale construction projects, meeting tight deadlines and quality standards.

- Welded pressure vessels and pipelines for the petrochemical industry, ensuring compliance with safety regulations and project specifications.

- Utilized advanced welding techniques, such as friction stir welding, to join lightweight alloys for aerospace applications.

- Collaborated with architects and contractors to develop customized metalwork designs, resulting in visually striking architectural features.

- Implemented lean manufacturing principles to streamline fabrication processes, reducing waste and increasing overall efficiency.

- Specialized in robotic welding programming and troubleshooting, optimizing production processes and minimizing downtime.

- Fabricated and welded complex assemblies for the defense industry, meeting strict quality and performance requirements.

- Operated automated laser cutting machines for precise metal cutting, increasing production output by 30%.

- Collaborated with research and development teams to prototype new welding methods, resulting in patent applications for innovative technologies.

- Conducted weld inspections using visual, dye penetrant, and magnetic particle testing, ensuring adherence to quality standards.

- Performed on-site welding repairs and maintenance for agricultural equipment, minimizing downtime and improving farm efficiency.

- Welded and fabricated steel frames and structures for industrial storage systems, ensuring durability and load-bearing capacity.

- Operated CNC press brakes and shearing machines to shape and form sheet metal components, optimizing material usage.

- Collaborated with production teams to implement continuous improvement initiatives, resulting in a 15% reduction in production cycle times.

- Conducted weld quality inspections and implemented corrective measures to improve weld integrity.

- Specialized in pipe welding for large-scale infrastructure projects, ensuring accurate alignment and strong welded joints.

- Fabricated and installed architectural metalwork for commercial buildings, meeting design specifications and aesthetic requirements.

- Operated heavy machinery, including forklifts and cranes, to move and position large metal components for welding assemblies.

- Collaborated with project teams to develop welding procedures and qualify welders according to industry standards and codes.

- Conducted weld inspections using radiographic and visual testing methods, ensuring compliance with quality and safety standards.

- Welded and repaired stainless steel tanks and vessels for the food and beverage industry, maintaining sanitary and hygienic conditions.

- Fabricated and installed conveyor systems for manufacturing facilities, optimizing material flow and enhancing production efficiency.

- Operated manual and semi-automatic welding equipment, such as stick and flux-cored arc welding machines, for versatile fabrication tasks.

- Collaborated with engineering teams to resolve design issues and recommend improvements in welding processes and techniques.

- Conducted weld quality inspections and implemented corrective actions to ensure compliance with industry standards.

The following content includes information from "O*NET OnLine" by the U.S. Department of Labor, Employment and Training Administration (USDOL/ETA). Used under the CC BY 4.0 license. The data represents the top responsibilities present on the task lists for welder fabricator professionals.

Top Responsibilities for Welder Fabricator:

- Operate safety equipment and use safe work habits.

- Examine workpieces for defects and measure workpieces with straightedges or templates to ensure conformance with specifications.

- Weld components in flat, vertical, or overhead positions.

- Detect faulty operation of equipment or defective materials and notify supervisors.

- Recognize, set up, and operate hand and power tools common to the welding trade, such as shielded metal arc and gas metal arc welding equipment.

- Select and install torches, torch tips, filler rods, and flux, according to welding chart specifications or types and thicknesses of metals.

- Mark or tag material with proper job number, piece marks, and other identifying marks as required.

- Determine required equipment and welding methods, applying knowledge of metallurgy, geometry, and welding techniques.

- Prepare all material surfaces to be welded, ensuring that there is no loose or thick scale, slag, rust, moisture, grease, or other foreign matter.

- Align and clamp workpieces together, using rules, squares, or hand tools, or position items in fixtures, jigs, or vises.

Quantifying impact on your resume

<ul>

Crafting the experience section for novice welder fabricator candidates

Lack of extensive experience doesn't equate to an empty resume. Here's how you can enrich your experience section:

- Volunteer Roles: Community involvement often equips you with valuable interpersonal skills, and sometimes even technical ones, relevant to the job.

- Academic Projects: Highlight significant university projects that contributed to the field, showcasing your hands-on experience.

- Internships: Even short-term internships can be invaluable. If they're pertinent to the role, they deserve a spot on your resume.

- Past Jobs: Even if unrelated to the welder fabricator, these roles can demonstrate transferable skills that are beneficial for the position.

Recommended reads:

Pro tip

If your experience section doesn't directly address the job's requirements, think laterally. Highlight industry-relevant awards or positive feedback to underscore your potential.

How to create an impactful welder fabricator resume skills section

Recruiters always care about the skill set you'd bring about to the welder fabricator role. That's why it's a good idea to cherry pick yours wisely, integrating both hard (or technical) and soft skills.

Hard skills are gained through studying, are certifiable, and it's impossible to do your job without them. All in all, they show your suitability for the technical aspect of the role.

Your soft skills are those personality traits you've gained over time and most often than not - outside of the workplace. Soft skills are more difficult to quantify but are definitely worth it - as they show how you'll fit and adapt into a new team environment.

How do you build the skills section of your resume?

- Include up to five or six skills in the section as keywords to align with the advert.

- Create a specific technical skills section to highlight your hard skills aptitude.

- Read more about the culture of the company you're applying and cherry pick the soft skills you have that deserve a mention.

- Make sure you answer the majority of the job requirements that are in the advert within your skills section.

A welder fabricator's resume requires a specific skill set that balances both industry-specific hard skills with personal, soft skills. Discover the most often used ones on welder fabricator resumes from our list:

Top skills for your welder fabricator resume:

MIG Welding

TIG Welding

Arc Welding

Plasma Cutting

Metal Fabrication

Blueprint Reading

Welding Equipment Operation

Welding Safety Procedures

CNC Machine Operation

Soldering

Attention to Detail

Problem Solving

Teamwork

Time Management

Adaptability

Communication Skills

Critical Thinking

Manual Dexterity

Creativity

Work Ethic

Next, you will find information on the top technologies for welder fabricator professonals from "O*NET OnLine" by the U.S. Department of Labor, Employment and Training Administration (USDOL/ETA). Used under the CC BY 4.0 license.

Top technologies for Welder Fabricator’s resume:

- IBM Notes

- Microsoft Outlook

- Scientific Software Group Filter Drain FD

- Value Analysis

- Oracle Database

- Recordkeeping software

Pro tip

Targeting the needed job ad skills doesn't have to end with the skills section. You can talk about your related certifications, interests or additional experience via projects or volunteering, where you picked up those skills, too.

Detailing your education and top welder fabricator certifications on your resume

Your education section can reflect a variety of skills and experiences relevant to the position.

- List post-secondary qualifications, noting the institution and duration.

- If you're currently studying, mention your expected graduation date.

- Exclude qualifications unrelated to the role or industry.

- If relevant, delve into your educational background, especially if it was research-intensive.

Including both relevant education and certifications on your welder fabricator resume can set you apart. It not only showcases your qualifications but also your commitment to the profession.

When listing these on your welder fabricator resume, make sure to:

- Highlight degrees and certificates relevant to the role.

- Mention the awarding institution for credibility.

- Include the start and end dates, or if the education/certification is ongoing.

- If relevant, incorporate a few keywords from the job advert within the description of the certification or degree.

If you have additional certifications not directly related to the role, consider placing them towards the end of your resume. This way, they can be viewed as personal interests rather than core qualifications.

For a quick update, check out our list of popular welder fabricator certifications curated by the Enhancv team.

Best certifications to list on your resume

Pro tip

The reputation of the institution or organization granting your certification or degree can bolster your credibility. Prioritize recognized and respected credentials.

Recommended reads:

Adding a summary or objective to your welder fabricator resume

One of the most crucial elements of your professional presentation is your resume's top one-third.

This most often includes:

- Either a resume summary - your career highlights at a glance. Select the summary if you have plenty of relevant experience (and achievements), you'd like recruiters to remember about your application.

- Or, a resume objective - to showcase your determination for growth. The perfect choice for candidates with less experience, who are looking to grow their career in the field.

If you want to go above and beyond with your welder fabricator resume summary or resume objective, make sure to answer precisely why recruiters need to hire you.

What is the additional value you'd provide to the company or organization?

Now here are examples from real-life welder fabricator professionals, whose resumes have helped them land their dream jobs:

Resume summary and objective examples for a welder fabricator resume

- With 10+ years of experience in the maritime industry, a certified welder fabricator proficient in MIG/TIG and stick welding, I've demonstrated mastery in fabricating custom parts for the shipbuilding sector. My work has contributed to reducing repair downtime by 30%.

- Highly skilled welder with over 15 years of expertise in the construction industry. Exemplary record of successfully executing complex projects within projected timeframes. Proficiency in SMAW, GMAW, and FCAW processes, resulting in improved operational efficiency by 25%.

- Adept mechanical engineer with 7 years of experience transitioning into the field of welding fabrication. Expertise in CAD/CAM software, material science, and structural analysis. Successfully led an engineering project that resulted in a patent and $500k annual savings.

- Detail-oriented architect with over 5 years of experience seeking to apply my blueprint reading skills and aesthetic principles in the field of welding fabrication. Proven ability to understand and implement design plans, resulting in structures that have won regional design awards.

- Passionate about joining the welding fabrication industry, leveraging my recently acquired AWS certification. My goal is to utilize my theoretical knowledge and hands-on training to contribute significantly to high-quality welding projects while continuously honing my technical skills.

- Eager to start a career in welding fabrication, capitalizing on my strong foundation in physics and mathematics obtained during my engineering degree. My aim is to apply problem-solving skills, attention to detail, and dedication to learning practical applications of welding techniques.

Optimize your resume summary and objective for ATS

Drop your resume here or choose a file.

PDF & DOCX only. Max 2MB file size.

Four additional sections to consider for your welder fabricator resume

To give a fuller picture of who you are, consider adding these sections to your welder fabricator resume:

- Awards - to showcase your achievements.

- Interests - to share passions outside of work.

- Publications - to highlight your contributions to the field.

- Projects - to spotlight significant accomplishments, even those outside of traditional work settings.

Key takeaways

- Pay special attention to the tiny details that make up your welder fabricator resume formatting: the more tailored your application to the role is, the better your chances at success would be;

- Select the sections you include (summary or objective, etc.) and formatting (reverse-chronological, hybrid, etc.) based on your experience level;

- Select experience items and, consequently, achievements that showcase you in the best light and are relevant to the job;

- Your profile will be assessed both based on your technical capabilities and personality skills - curate those through your resume;

- Certifications and education showcase your dedication to the particular industry.