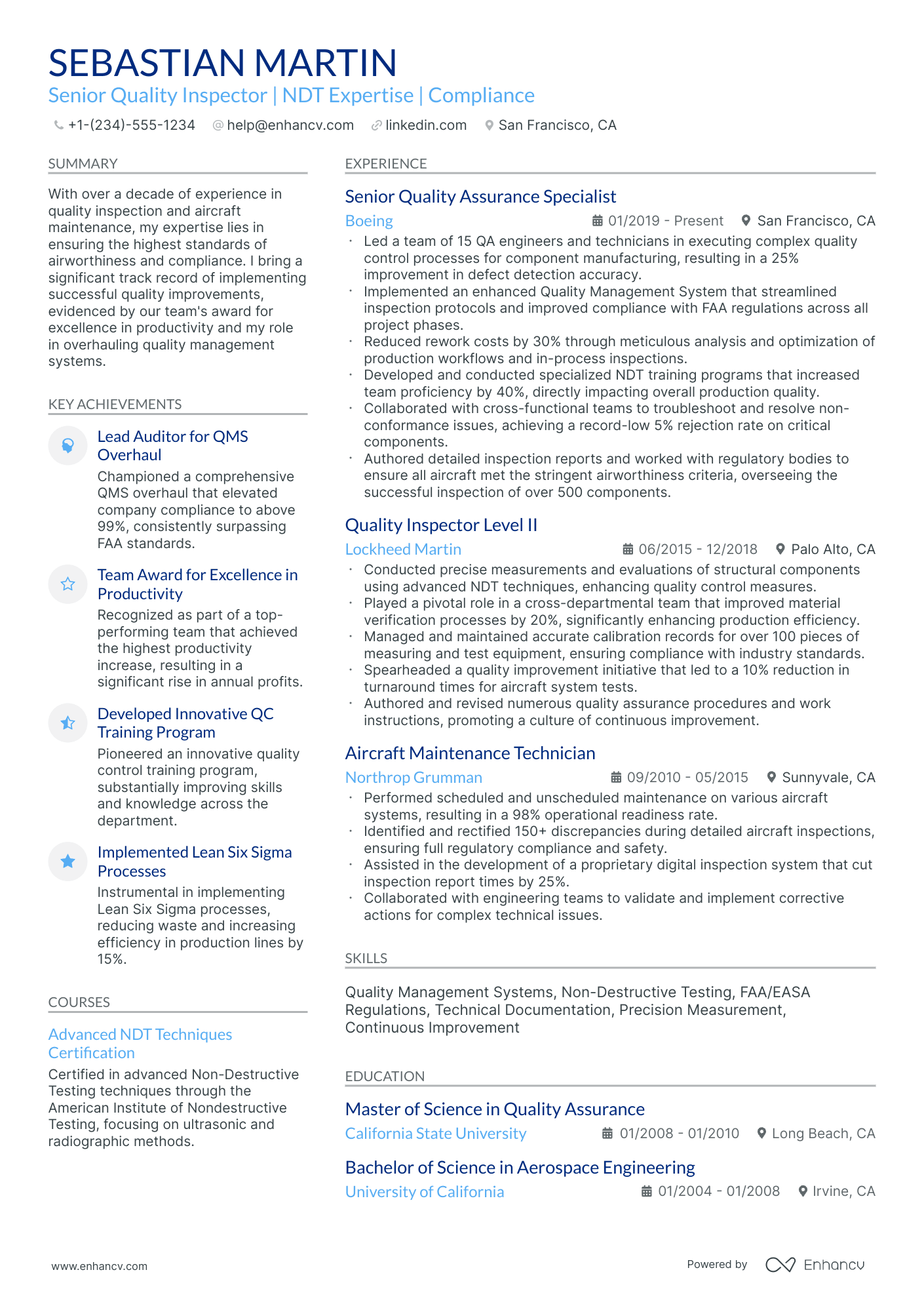

As a quality inspector, articulating your keen attention to detail and vast knowledge of compliance standards can be a daunting task when crafting your resume. Our guide provides targeted advice to showcase your expertise effectively, ensuring that your proficiency in maintaining the highest levels of product quality shines through to potential employers.

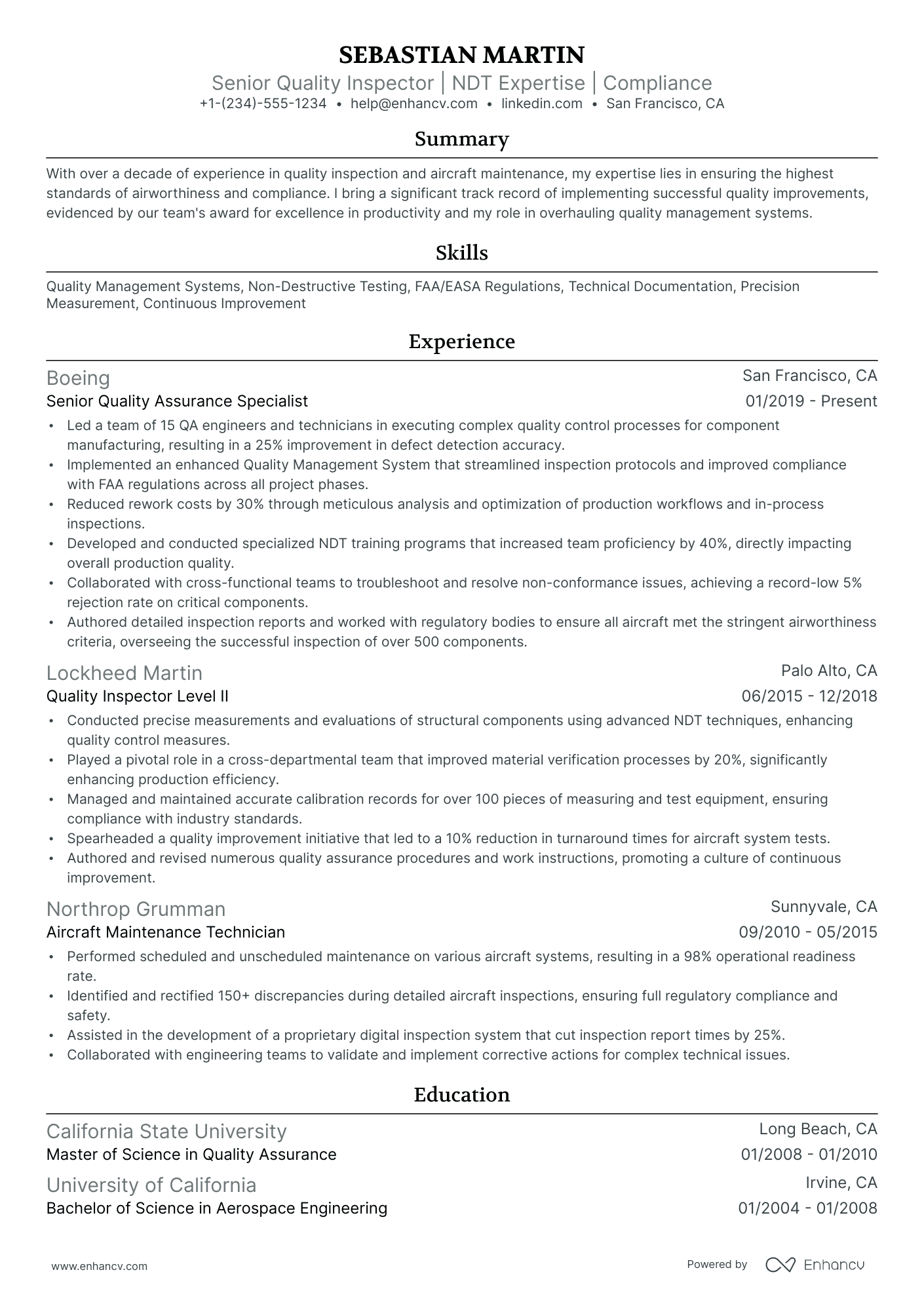

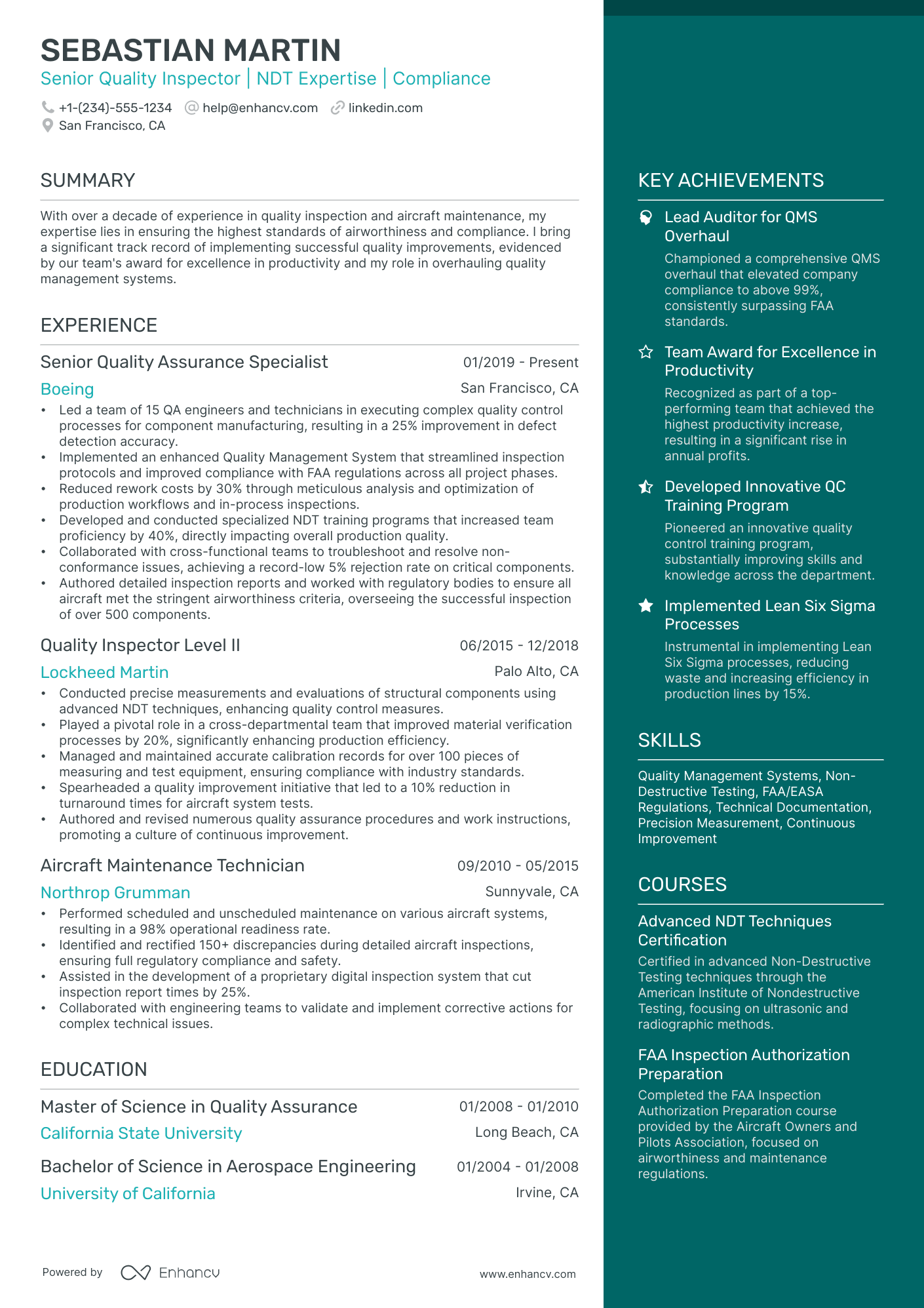

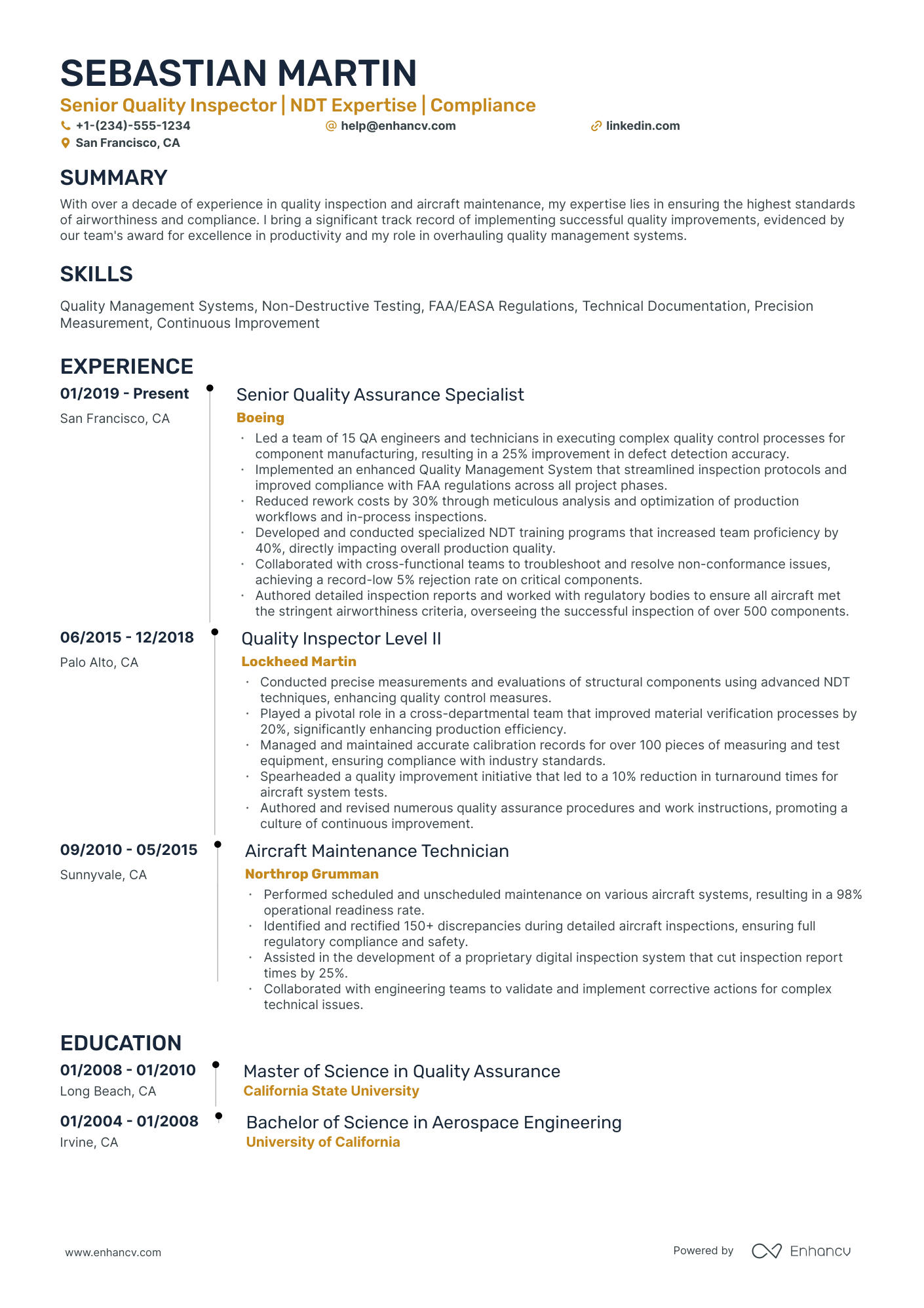

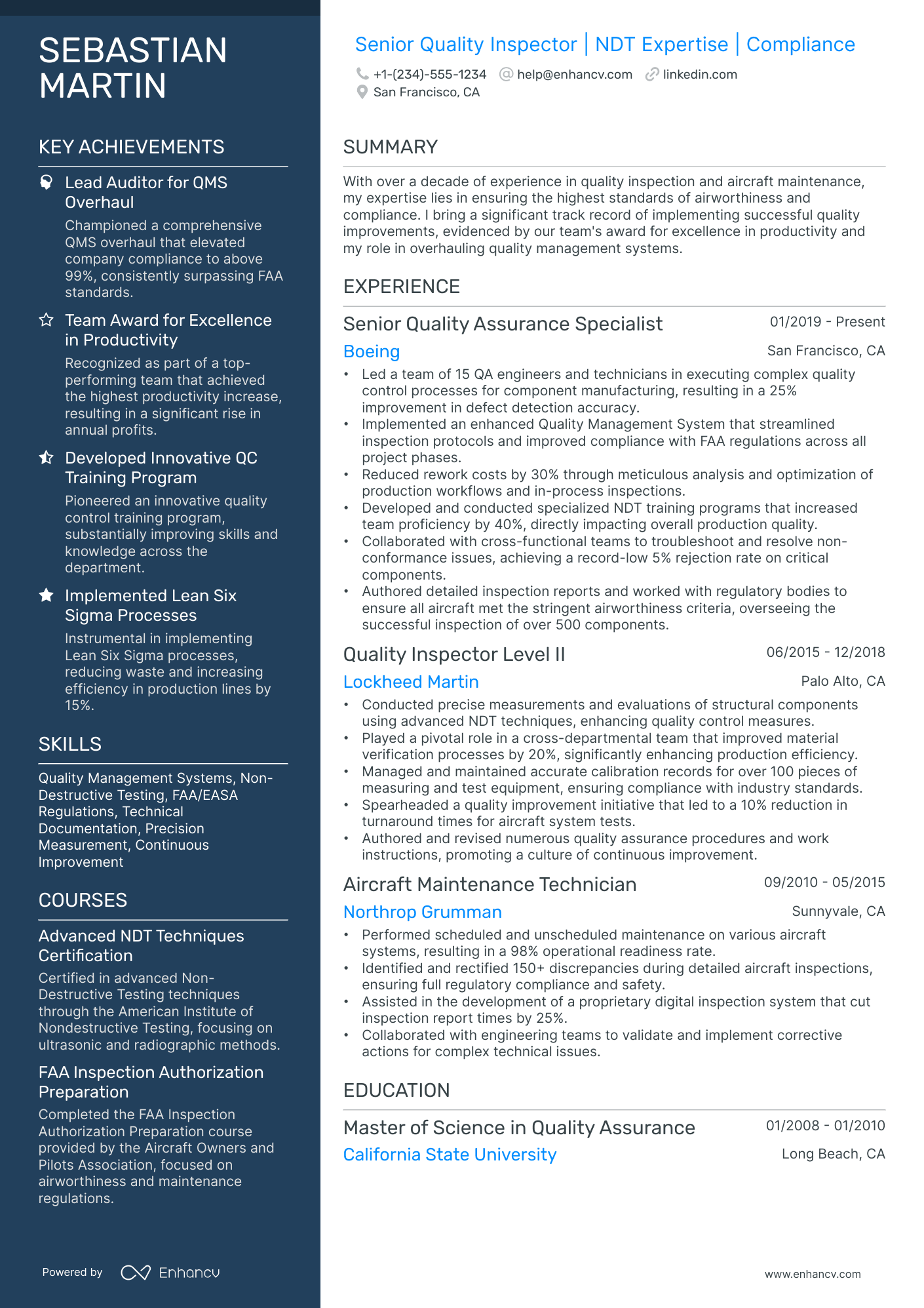

- The most straightforward and effective resume format, ensuring your quality inspector resume stands out among numerous candidate profiles;

- The significance of the top one-third of your resume, including the header, summary or objective, and skills section, and its impact on recruiters;

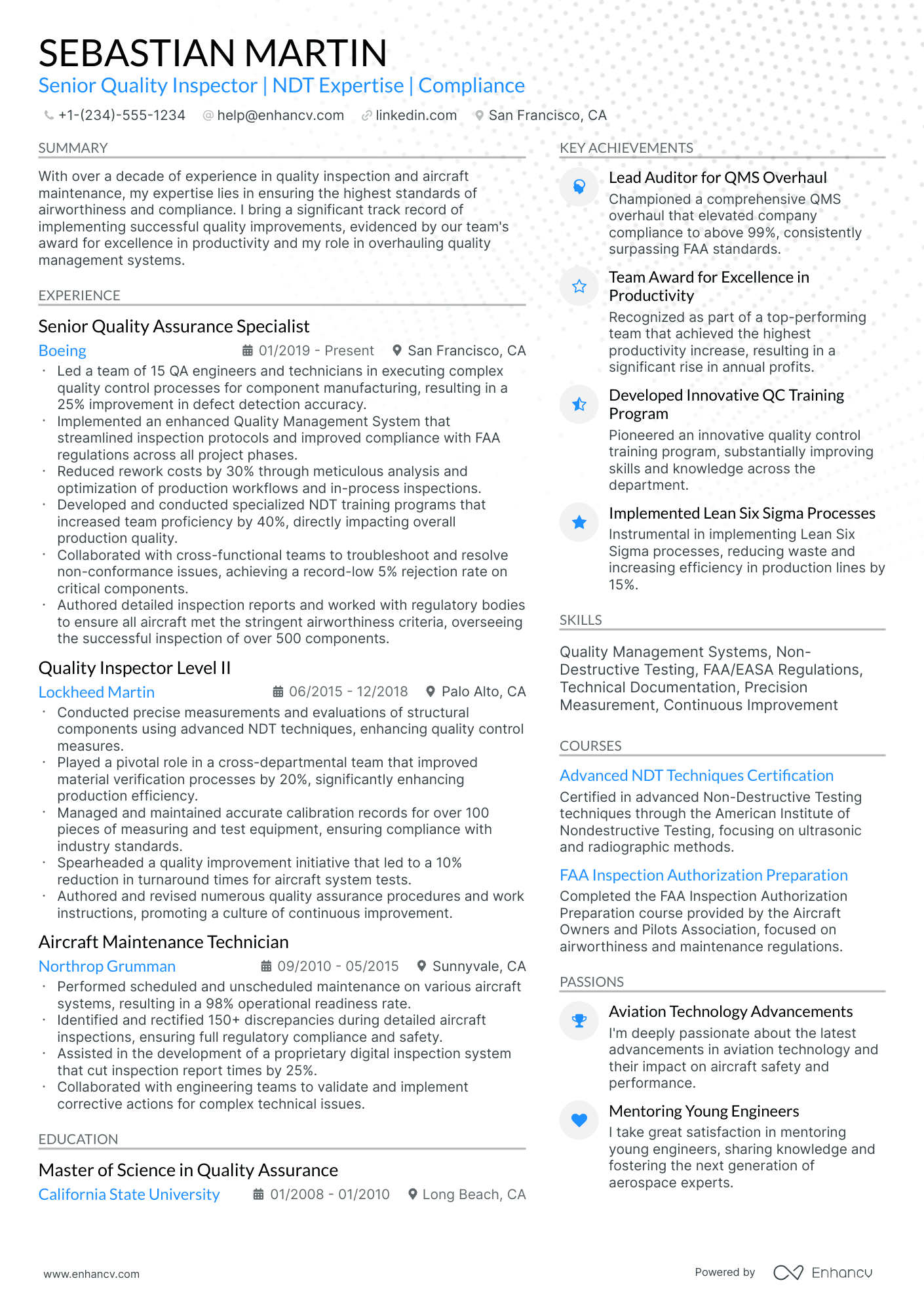

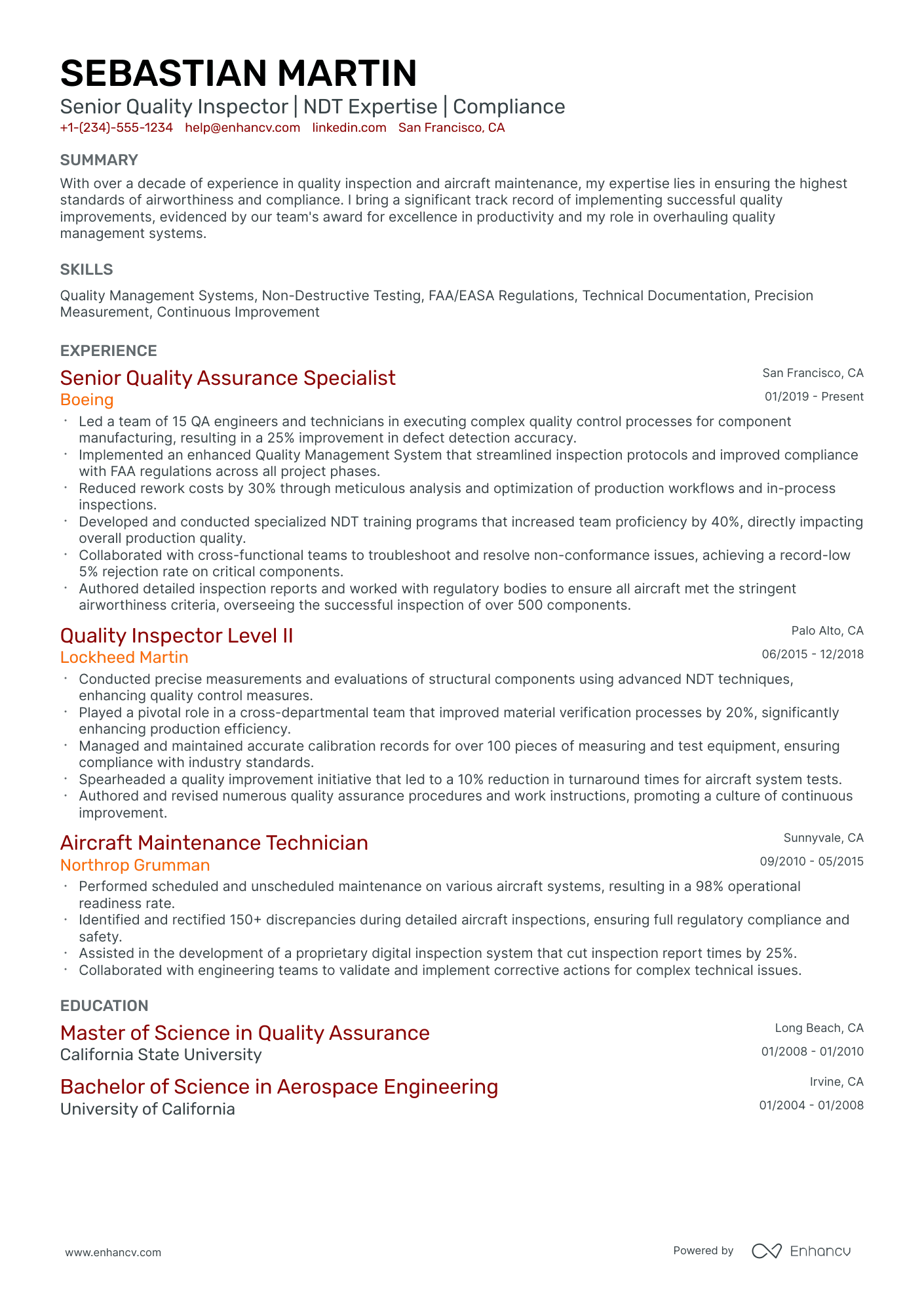

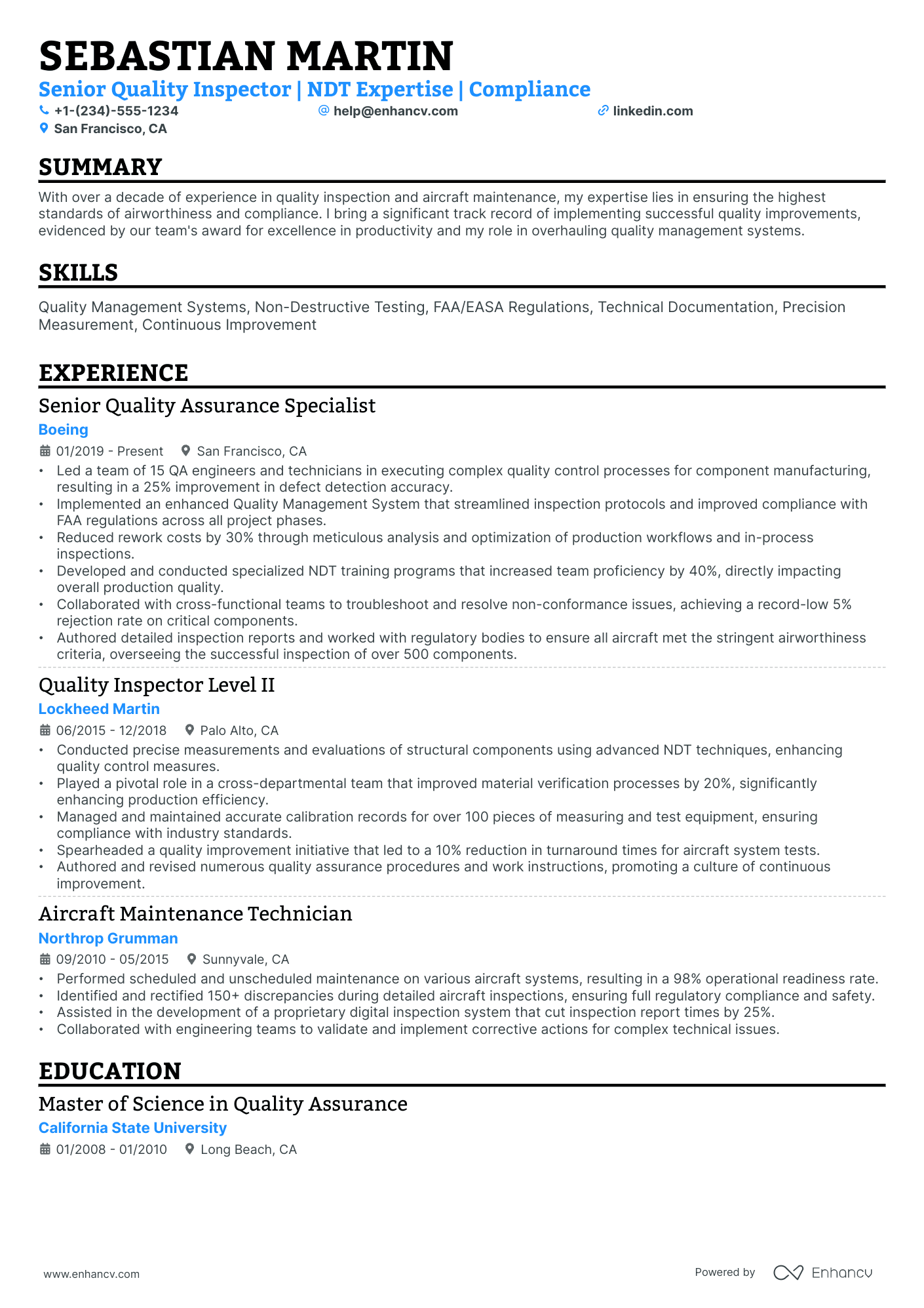

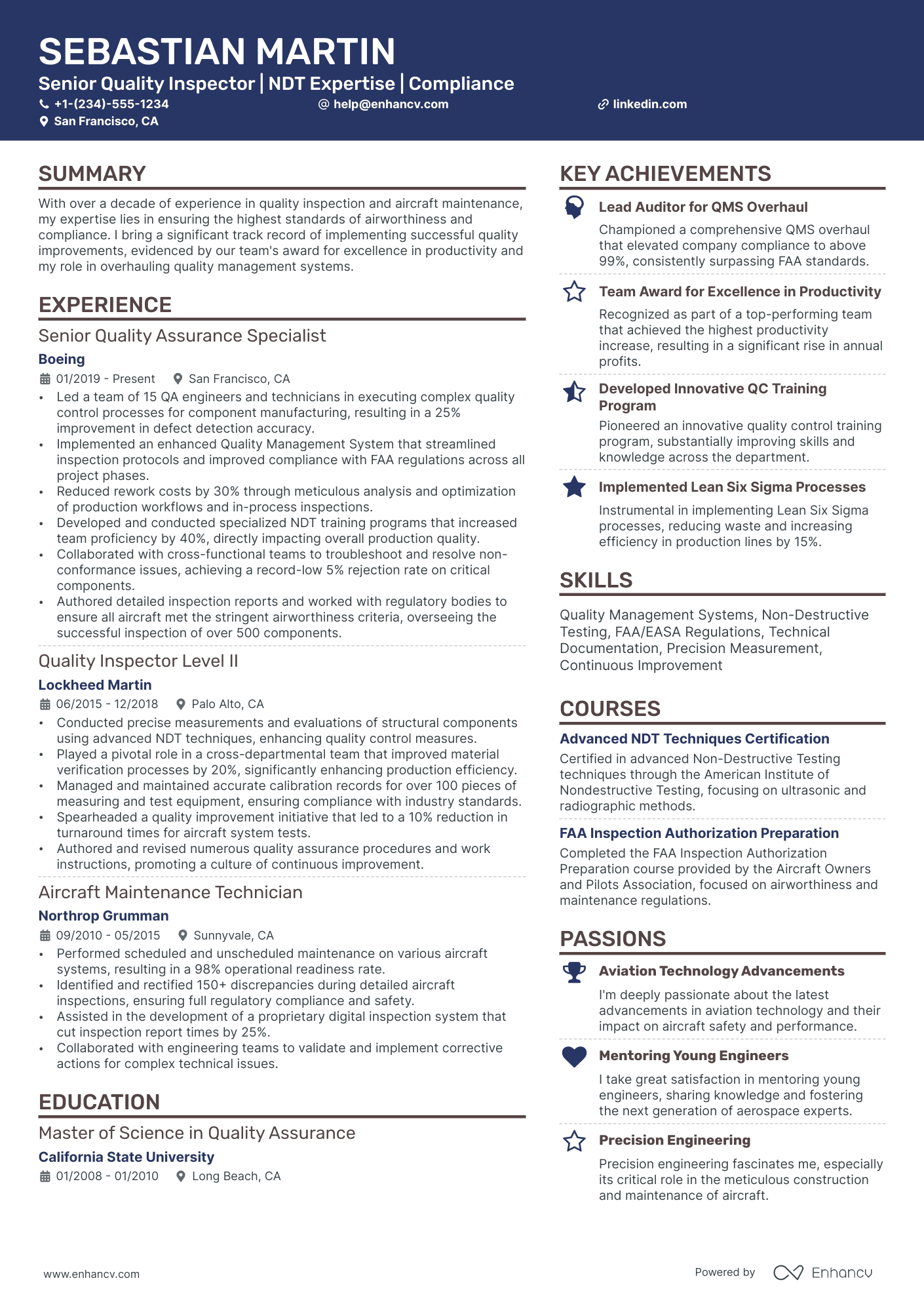

- Frameworks and structures used by real quality inspector professionals, offering insights on how to enhance your resume with industry-specific expertise;

- A variety of quality inspector resume sections that bolster your profile, showcasing your comprehensive capabilities and distinctiveness.

Gaining insights from the best has never been easier. Explore more quality inspector resume examples below:

- Quality Assurance Associate Resume Example

- Quality Manager Resume Example

- Quality Assurance Specialist Resume Example

- Quality Assurance Auditor Resume Example

- Quality Assurance Technician Resume Example

- Quality Assurance Analyst Resume Example

- Quality Specialist Resume Example

- Quality Control Manager Resume Example

The ultimate formula for your quality inspector resume format

Our best advice on how to style your quality inspector resume is this - first, take the time to study the job advert requirements.

The resume format you select should ultimately help you better align how your experience matches the specific role.

There are four crucial elements you need to thus take into consideration:

- How you present your experience. If you happen to have plenty of relevant expertise, select the reverse-chronological resume format to organize your experience by dates, starting with the latest.

- Don't go over the top with writing your resume. Instead, stick with a maximum of two-page format to feature what matters most about your profile.

- Headers aren't just for "decoration". The header of your resume helps recruiters allocate your contact details, portfolio, and so much more.

- The PDF format rules. It's the most common practice to submit your quality inspector resume as a PDF so that your resume doesn't lose its layout. However, make sure the read the job well - in some instances, they might require a doc file.

Your resume should match the market – Canadian applications, for instance, may use a different layout.

Upload & Check Your Resume

Drop your resume here or choose a file. PDF & DOCX only. Max 2MB file size.

PRO TIP

The more time and effort you've put into obtaining the relevant certificate, the closer to the top it should be listed. This is especially important for more senior roles and if the company you're applying for is more forward-facing.

Don't forget to include these six sections on your quality inspector resume:

- Header and summary for your contact details and to highlight your alignment with the quality inspector job you're applying for

- Experience section to get into specific technologies you're apt at using and personal skills to deliver successful results

- Skills section to further highlight how your profile matches the job requirements

- Education section to provide your academic background

- Achievements to mention any career highlights that may be impressive, or that you might have missed so far in other resume sections

What recruiters want to see on your resume:

- Demonstrating knowledge of quality standards such as ISO 9001, Six Sigma, or industry-specific standards

- Experience with quality inspection tools and methods, for example, calipers, micrometers, and statistical process control techniques

- Attention to detail with a proven ability to identify defects and inconsistencies in products or processes

- Strong analytical skills and familiarity with data analysis/reporting tools to manage quality-related metrics

- Relevant certifications such as Certified quality inspector (CQI) or Certified Quality Engineer (CQE) from the American Society for Quality (ASQ)

Guide to your most impressive quality inspector resume experience section

When it comes to your resume experience , stick to these simple, yet effective five steps:

- Show how your experience is relevant by including your responsibility, skill used, and outcome/-s;

- Use individual bullets to answer how your experience aligns with the job requirements;

- Think of a way to demonstrate the tangible results of your success with stats, numbers, and/or percentages ;

- Always tailor the experience section to the quality inspector role you're applying for - this may sometimes include taking out irrelevant experience items;

- Highlight your best (and most relevant) achievements towards the top of each experience bullet.

You're not alone if you're struggling with curating your experience section. That's why we've prepared some professional, real-life quality inspector resume samples to show how to best write your experience section (and more).

- Conducted thorough examinations of over 150 batches of manufactured electronic components, ensuring adherence to both internal and ISO 9001 standards.

- Led a quality improvement project that reduced manufacturing defects by 23% through enhanced inspection protocols and employee training sessions.

- Collaborated closely with production teams to identify root causes of quality issues and implemented procedural changes that increased overall product reliability by 30%.

- Managed the initiation and execution of a quality control system that streamlined the inspection process for a high-volume automotive parts manufacturer, leading to a 15% improvement in inspection time per part.

- Established and conducted regular training programs for new quality inspectors, resulting in a 20% increase in inspection accuracy across the team.

- Authored comprehensive inspection reports and provided key recommendations to senior management to guide continuous improvement efforts.

- Instrumental in developing and implementing advanced non-destructive testing techniques utilizing ultrasonic and radiographic methods on over 500 components, which led to the discovery of previously undetectable defects.

- Played a crucial role in the certification process for new aerospace materials, ensuring compliance with stringent industry and federal regulations.

- Assisted in the transition to an automated inspection system, which reduced human error and increased throughput by 40%.

- Oversaw quality control processes for pharmaceutical packaging, maintaining compliance with FDA regulations and reducing material waste by 10% through efficient inspection practices.

- Implemented statistical process control methods to monitor and control quality parameters, resulting in a 25% reduction in batch rejections.

- Coordinated with cross-functional teams to address customer complaints and implement corrective actions that enhanced customer satisfaction by 35%.

- Facilitated the introduction of a lean manufacturing approach to the inspection process, cutting inspection cycle times by 20% while maintaining product quality.

- Carried out detailed dimensional inspections on precision-engineered components, ensuring that tolerances met strict industry standards.

- Initiated a quality control circle within the inspection team that successfully identified and eliminated recurrent defects, boosting product consistency.

- Maintained responsibility for inspecting over 200 different food products, ensuring compliance with USDA regulations and achieving a 99.8% pass rate on external audits.

- Utilized Six Sigma methodologies to reduce process variation and improve product quality, resulting in a 12% decrease in customer complaints.

- Championed a cross-departmental effort to recalibrate inspection equipment, thereby improving accuracy by 18% and enhancing overall production efficiency.

- Reviewed and approved quality-related documentation for a major construction project, ensuring all materials and workmanship met or exceeded project specifications.

- Developed a streamlined inspection checklist which improved team productivity and was adopted company-wide.

- Delivered monthly quality reports that provided insightful data analysis, enabling project managers to make informed decisions about process improvements.

- Instrumental in the implementation of a cutting-edge electronic inspection system for textile manufacturing, increasing detection of fabric imperfections by 25%.

- Guided a team in the meticulous inspection of over 500,000 units of apparel, maintaining the company's reputation for high-quality products.

- Organized and led weekly quality assurance meetings to track progress, discuss findings, and exchange best practices with a focus on continuous improvement.

- Played a key role in the rollout of a global quality management system for a leading consumer electronics company, resulting in harmonization of quality standards at all international facilities.

- Successfully managed the inspection and compliance of over 1 million electronic devices, enhancing the brand's reputation for quality and reliability.

- Developed a supplier quality scoring system that improved supplier selection and performance, leading to a 15% decrease in defect rates from external sources.

- Worked on a dedicated task force to prepare for ISO 13485 medical device certification, which was successfully attained within a 12-month period.

- Expertly conducted biocompatibility testing on over 200 medical device prototypes, ensuring conformance to industry safety standards.

- Executed a tailored quality training program for junior inspectors, significantly increasing their efficiency and competency in complex inspection tasks.

The following content includes information from "O*NET OnLine" by the U.S. Department of Labor, Employment and Training Administration (USDOL/ETA). Used under the CC BY 4.0 license. The data represents the top responsibilities present on the task lists for quality inspector professionals.

Top Responsibilities for Quality Inspector:

- Document quantity, quality, type, weight, test result data, and value of materials or products to maintain shipping, receiving, and production records and files.

- Weigh or measure materials, equipment, or products to maintain relevant records, using volume meters, scales, rules, or calipers.

- Collect or prepare measurement, weight, or identification labels and attach them to products.

- Examine products or materials, parts, subassemblies, and packaging for damage, defects, or shortages, using specification sheets, gauges, and standards charts.

- Signal or instruct other workers to weigh, move, or check products.

- Collect product samples and prepare them for laboratory analysis or testing.

- Maintain, monitor, and clean work areas, such as recycling collection sites, drop boxes, counters and windows, and areas around scale houses.

- Compare product labels, tags, or tickets, shipping manifests, purchase orders, and bills of lading to verify accuracy of shipment contents, quality specifications, or weights.

- Remove from stock products or loads not meeting quality standards, and notify supervisors or appropriate departments of discrepancies or shortages.

- Inspect products and examination records to determine the number of defects per worker and the reasons for examiners' rejections.

Quantifying impact on your resume

- Include the number of quality audits performed to demonstrate experience and diligence in applying quality standards.

- Specify the percentage reduction in defect rates achieved through quality initiatives to highlight problem-solving skills.

- Mention the exact number of quality control processes optimized to showcase process improvement capabilities.

- List the number of team members trained in quality assurance practices to reflect leadership and mentorship qualities.

- Cite the dollar value of cost savings realized from quality improvements to demonstrate a direct impact on the bottom line.

- Document the number of regulatory inspections passed, indicating compliance expertise and the ability to meet industry standards.

- State the range or average scores of customer satisfaction surveys related to product quality to emphasize customer-centric results.

- Provide the number of standard operating procedures (SOPs) written or revised, illustrating the commitment to quality and procedural discipline.

Action verbs for your quality inspector resume

What to do if you don't have any experience

It's quite often that candidates without relevant work experience apply for a more entry-level role - and they end up getting hired.

Candidate resumes without experience have these four elements in common:

- Instead of listing their experience in reverse-chronological format (starting with the latest), they've selected a functional-skill-based format. In that way, quality inspector resumes become more focused on strengths and skills

- Transferrable skills - or ones obtained thanks to work and life experience - have become the core of the resume

- Within the objective, you'd find career achievements, the reason behind the application, and the unique value the candidate brings about to the specific role

- Candidate skills are selected to cover basic requirements, but also show any niche expertise.

Recommended reads:

PRO TIP

The more trusted the organization you've attained your certificate (or degree) from, the more credible your skill set would be.

Featuring your hard skills and soft skills on your quality inspector resume

The skills section of your quality inspector resume needs to your various capabilities that align with the job requirements. List hard skills (or technical skills) to showcase to potential employers that you're perfectly apt at dealing with technological innovations and niche software. Meanwhile, your soft skills need to detail how you'd thrive within your new, potential environment with personal skills (e.g. resilience, negotiation, organization, etc.) Your quality inspector resume skills section needs to include both types of skills to promote how you're both technical and cultural fit. Here's how to create your bespoke quality inspector skills section to help you stand out:

- Focus on skill requirements that are listed toward the top of the job advert.

- Include niche skills that you've worked hard to obtain.

- Select specific soft skills that match the company (or the department) culture.

- Cover some of the basic job requirements by including important skills for the quality inspector role - ones you haven't been able to list through the rest of your resume.

Get inspired with our quality inspector sample skill list to list some of the most prominent hard and soft skills across the field.

Top skills for your quality inspector resume:

ISO Standards Knowledge

Statistical Process Control (SPC)

Quality Management Systems (QMS)

Calipers and Micrometers

Inspection Software (e.g., Minitab)

Non-Destructive Testing (NDT)

Root Cause Analysis

Blueprint Reading

Measurement and Testing Equipment

Lean Manufacturing Principles

Attention to Detail

Analytical Thinking

Problem-Solving

Communication Skills

Team Collaboration

Time Management

Adaptability

Critical Thinking

Decision Making

Conflict Resolution

Next, you will find information on the top technologies for quality inspector professonals from "O*NET OnLine" by the U.S. Department of Labor, Employment and Training Administration (USDOL/ETA). Used under the CC BY 4.0 license.

Top technologies for Quality Inspector’s resume:

- Oracle JD Edwards EnterpriseOne

- SAP software

- Microsoft PowerPoint

- Email software

- Microsoft Outlook

PRO TIP

If you're in the process of obtaining your certificate or degree, list the expected date you're supposed to graduate or be certified.

Listing your education and certifications on your quality inspector resume

Don't underestimate the importance of your resume education section . As it may hint at various skills (and experience) that are relevant to the job. When writing your education section:

- Include only higher education degrees with information about the institution and start/end dates

- If you're in the process of obtaining your degree, include your expected graduation date

- Consider leaving off degrees that aren't relevant to the job or industry

- Write a description of your education if it presents you with an opportunity to further showcase your achievements in a more research-focused environment

When describing your certifications on your resume, always consider their relevancy to the role. Use the same format to describe them as you would for your education. If you're wondering what the best certificates out there are for quality inspector roles, check out the list below.

The top 5 certifications for your quality inspector resume:

- Certified quality inspector (CQI) - American Society for Quality (ASQ)

- Certified Quality Technician (CQT) - American Society for Quality (ASQ)

- ISO 9001:2015 Certified Lead Auditor (CLA) - Exemplar Global

- Quality Process Analyst Certification (CQPA) - American Society for Quality (ASQ)

- Six Sigma Green Belt Certification (SSGB) - American Society for Quality (ASQ)

The content below includes information from "O*NET OnLine" by the U.S. Department of Labor, Employment and Training Administration (USDOL/ETA). Used under the CC BY 4.0 license. The data represents the top associations for quality inspector professionals.

Top US associations for a Quality Inspector professional

- MHI

- National Association of Wholesaler-Distributors

- Warehousing Education and Research Council

PRO TIP

List all your relevant higher education degrees within your resume in reverse chronological order (starting with the latest). There are cases when your PhD in a particular field could help you stand apart from other candidates.

Recommended reads:

Practical guide to your quality inspector resume summary or objective

First off, should you include a summary or objective on your quality inspector resume?

We definitely recommend you choose the:

- Resume summary to match job requirements with most noteworthy accomplishments.

- Resume objective as a snapshot of career dreams

Both the resume summary and objective should set expectations for recruiters as to what your career highlights are.

These introductory paragraphs (that are no more than five sentences long) should help you answer why you're the best candidate for the job.

Industry-wide best practices pinpoint that the quality inspector resume summaries and objectives follow the structures of these samples:

Resume summaries for a quality inspector job

- Dedicated quality inspector with 7 years of experience in high-volume manufacturing environments, adept at conducting meticulous quality checks per ISO 9001 standards. Leverages extensive knowledge of statistical process control and lean manufacturing to enhance product quality and production efficiency, culminating in a 20% defect reduction at Zenith Electronics.

- A tenacious former Aerospace Engineer pivoting to Quality Inspection, bringing a strong analytical mindset, proficiency in CAD software, and 5 years of experience in design validation for international aviation projects. Recognized for implementing a monitoring system that improved component reliability by 35%, now seeking to apply technical skills to safeguard manufacturing quality.

- Experienced Pharmaceutical Lab Technician transitioning to the Quality Inspection field, with a solid foundation in regulatory compliance, chemical analysis, and quality control procedures. Known for championing a significant improvement in lab testing turnaround times by 25%, aiming to apply a detail-oriented approach to uphold product standards in a new industry.

- Aspiring to advance as a quality inspector, bringing a fresh perspective and unyielding commitment to excellence in a new industry. With a degree in Industrial Engineering and an internship experience focusing on process optimization, eager to develop an expertise in quality control while contributing to the operational effectiveness of manufacturing processes.

- Energetic professional seeking an entry-level quality inspector role, armed with a Bachelor's degree in Mechanical Engineering and a passion for precision engineering. Motivated by a capstone project which enhanced the quality of 3D printed prototypes, ready to acquire hands-on experience in quality assurance systems and drive continuous improvement initiatives.

- After a 8-year tenure as an ISO-certified Process Technician in the semiconductor industry, with a track record of slashing defect rates by 30% through rigorous process auditing, I am now targeting a role in Quality Inspection. With a sharp eye for accuracy and a commitment to upholding the highest quality standards, I'm set to ensure excellence in product outcomes.

Optimize your resume summary and objective for ATS

Drop your resume here or choose a file.

PDF & DOCX only. Max 2MB file size.

Average salary info by state in the US for quality inspector professionals

Local salary info for Quality Inspector.” Source: My Next Move, National Center for O*NET Development. Accessed 10/15/2024

| State | Average Salary (in USD) |

|---|---|

| US National Average | $43,270 |

| California (CA) | $44,770 |

| Texas (TX) | $42,740 |

| Florida (FL) | $41,560 |

| New York (NY) | $43,470 |

| Pennsylvania (PA) | $47,410 |

| Illinois (IL) | $45,040 |

| Ohio (OH) | $39,760 |

| Georgia (GA) | $43,310 |

| North Carolina (NC) | $38,770 |

| Michigan (MI) | $44,420 |

Bonus sections for your quality inspector resume

Looking to show more personality on your quality inspector resume? Then consider including a couple of extra sections.

They'd benefit your application by highlighting your most prominent:

Key takeaways

- Ensure your quality inspector resume uses a simple, easy-to-read format that reflects upon your experience and aligns with the role;

- Be specific within the top one-third of your resume (header and summary or objective) to pinpoint what makes you the ideal candidate for the quality inspector role;

- Curate information that is tailored to the job by detailing skills, achievements, and actual outcomes of your efforts;

- List your certifications and technical capabilities to demonstrate your aptitude with specific software and technologies;

- The sections you decide on including on your quality inspector should pinpoint your professional expertise and personality.